Global Provider of Custom Ruggedized Coatings and Engineering Solutions

At Plasma Ruggedized Solutions (PRS), we specialize in high-quality parylene coating, proprietary plasma technologies, potting and encapsulation, and full-service manufacturing. With over 20 years of experience, our engineering expertise is backed by rigorous quality assurance, earning NADCAP, AS9100, and NASA certifications and compliance with AS9100, RoHS, ITAR, and other industry standards.

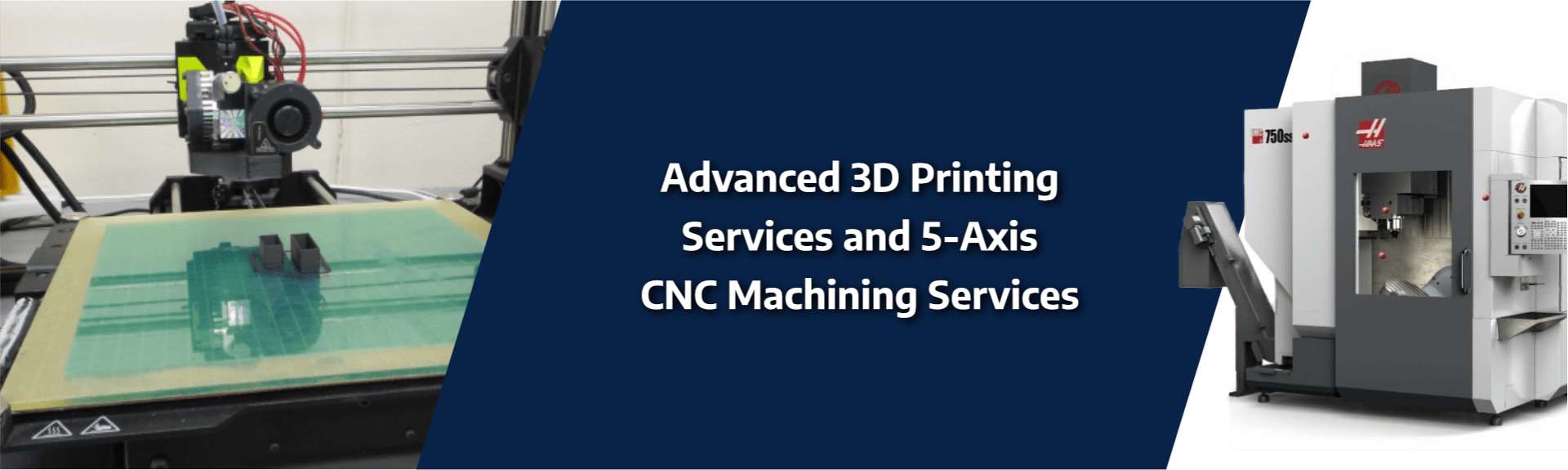

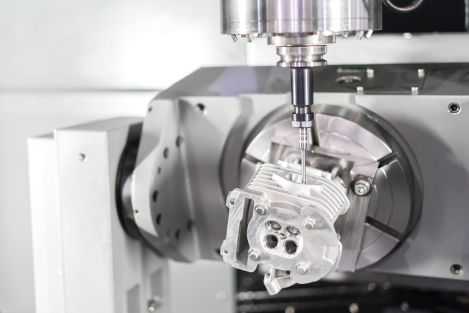

With locations in San Jose and Huntington Beach, California, PRS operates more than 40,000 square feet of advanced manufacturing space, allowing us to support high-volume production across various industries such as aerospace, defense, medical, and industrial manufacturing. Our full-service fabrication capabilities, including 5-axis CNC machining, enable us to produce complex, high-precision components that meet the most demanding engineering requirements.

PRS is also a trusted partner for critical government agencies, including the Missile Defense Agency (MDA). Our ruggedized coatings and engineering solutions ensure long-term reliability for electrical and mechanical applications operating in extreme environments, delivering the durability and protection needed for mission-critical systems. Contact Us

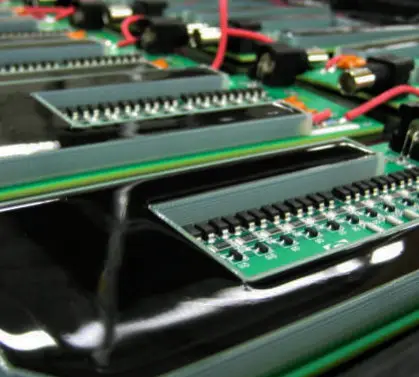

Conformal Coatings

Our conformal coating services offer protection against contaminants and environmental factors for electronic assemblies. Conformal coatings are developed to deliver specialty engineering solutions. Selecting an application method and material that addresses your needs, we maximize quality and performance by tailoring our processes to project specifications.

For an in-depth understanding, check out our Ultimate Guide to Conformal Coating.

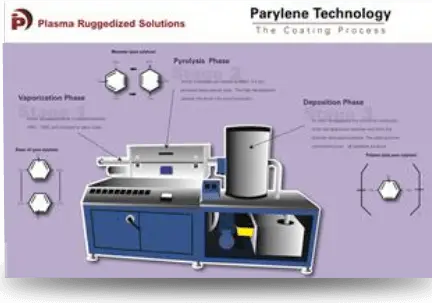

Parylene Coatings

Delivering a thinner protective layer than other coating processes, parylene coating services offer electrical properties and high chemical resistance. Parylene coating has advantages over traditional coating methods. Using vacuum deposition, parylene coatings can permeate crevices without clogging or blocking device components for critical applications.

Potting and Encapsulation

Potting and encapsulation protect electronic assemblies against harsh environments, security threats (FIPS Level 4 available), and tin whisker formation. We can adapt to project needs with in-house molding systems and fixtures. Able to provide services for any quantity, we work with you to choose a process that meets your requirements.

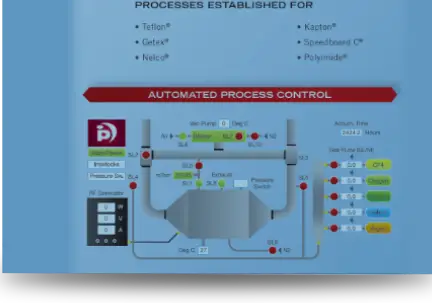

Plasma Etchback & Desmear Treatments

PRS plasma etchback and desmear treatments ensure circuit reliability and performance by removing residues left by manufacturing processes. Highly repeatable, environmentally conscious plasma treatments are proven methods for residue removal, and our in-house laboratory prepares your PCBs for their next stage.

Specialized Chemical Resistance Coatings

PRS offers chemical resistance coatings to provide protective solutions for electrical and mechanical components in various industrial applications. Protecting against moisture, challenging environmental factors, security theft, and chemical exposure, our specialized resistance coatings include:

- Polyurethane Conformal Coatings

- Parylene (Polyparaxylylene) Coatings

- Ball Grid Array Underfill Materials

- PRS IP Formulated Materials

Green Operations & Quality Certifications

We are proud to be an organization dedicated to maintaining and enhancing our environmentally responsible operations. Using processes that prioritize a low output of volatile organic compounds (VOCs), our commitment is underscored by conscious choices in chemistries and compounds that are environmentally friendly. Additionally, Plasma Ruggedized Solutions’ Next Generation Technologies offers eco-conscious repairs, touch-ups, and stripping processes to revitalize viable equipment for reuse.

Compliant with multiple quality certifications and accreditations, our capabilities are compatible with a broad range of industries and applications.

Green OperationsProprietary Ruggedized Engineering Solutions

Plasma Ruggedized Solutions has conformal coatings and specialty engineering solutions using methodologies developed by our experts. Our proprietary approaches and materials are designed to provide high-performance protection for electrical and mechanical applications. We comply with the Federal Information Processing Standards (FIPS), making PRS the choice for security-oriented customers in public, private, and government sectors. We can design, formulate, and build our equipment, chemistry, and fixtures to your project requirements.

With a 5-7 day turnaround and quality assured, we deliver products and services tailored to your needs.

FIPS Compliance

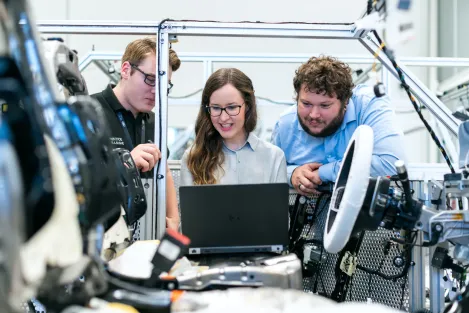

Comprehensive Production and Engineering Services

In addition to conformal coating services, we are also a full-service fabricator and manufacturer. We offer production and engineering services to design and manufacture custom solutions. Our accreditations confirm that our products and services achieve the highest levels of quality to meet strict standards in various industries.

We can provide a range of design, prototyping, and engineering services to optimize components and assemblies. With advanced 3D printing services, molding services, and 5-axis CNC machining, we can create high-quality products to meet project needs. PRS production and engineering services include form-in-place gaskets, testing, screening, and laboratory capabilities.

Our Services

Customer Care

Plasma Ruggedized Solutions embodies a customer-centric culture committed to meeting the ever-changing, complex requirements of our global customer base. An eco-friendly, RoHS-compliant company, PRS focuses on producing proper technical solutions and addressing environmental factors of an operational solution. We aim for total customer satisfaction through our core values: exceptional, adaptive product and service offerings, next-generation manufacturing techniques, high first-time yields, and on-time delivery. Working with you, we aspire to build responsive, communicative, and flexible business relationships to fulfill your conformal coating and specialty engineering needs.

Contact Us