Ruggedization, Conformal Coating & Electronic Protection Services

View Under UV Light

Conformal Coating Services

Plasma Ruggedized Solutions delivers advanced ruggedization services across multiple industries, providing customized solutions for demanding applications.

As a leading provider of Acrylic, Silicone, Urethane, and Parylene (Polyparaxylylene) coatings, we specialize in high-precision protective solutions. Our engineering expertise and state-of-the-art production facilities support a wide range of services, including potting/encapsulation, plasma etch-back and desmear, BGA underfill, laboratory testing, and precision 5-axis CNC machining.

With AS9100, NASA, and ITAR certifications, our engineering and production processes meet the most stringent quality standards, ensuring the reliability and longevity of your components. Want to understand the full value our services deliver? Learn more about our engineering value.

Explore our full range of production & engineering services below. Not sure where to start? Contact Plasma Ruggedized Solutions Contact Us to discuss your project today.

Conformal Coating & Inspection Services

We specialize in the application of acrylics/silicone/urethane conformal coating services designed to meet your specific industry goals. Better protect your electronics against corrosion, contaminants, leakage, salt, and other severe conditions with cutting-edge Blue Spark™, Kronos-10, and Kryptos-17 coating solutions.

Parylene Coating Services

Protect components, devices, and services with our perfectly uniform vacuum-deposition Parylene (Polyparaxylylene) coating services. Parylene coatings offer high chemical resistance, superior electrical properties and are the only conformal coating material that is FDA-approved for medical implantation. Protect your assemblies with a thinner, more temperature-resistant coating film that has been proven effective across a variety of industries.

Electronic Potting & Encapsulation

Our potting and encapsulation services provide a physically robust solution to protect PCBs and assemblies in challenging environments. Potting/encapsulation enhances circuit reliability by eliminating current leakage while also protecting against voltage arcs and short circuits by preventing tin whisker growth.

LED Display Coatings & Encapsulation

Our coatings & encapsulation services are designed to protect against the functional and physical degradation of components when they are exposed to challenging or harsh environments. PRS’s thin film solutions for LED’s and electronics offer superior protection without affecting the components’ optical or light transmission properties.

Request a quote on Plasma Ruggedized Solutions’ production & engineering services today or contact us with any questions you have.

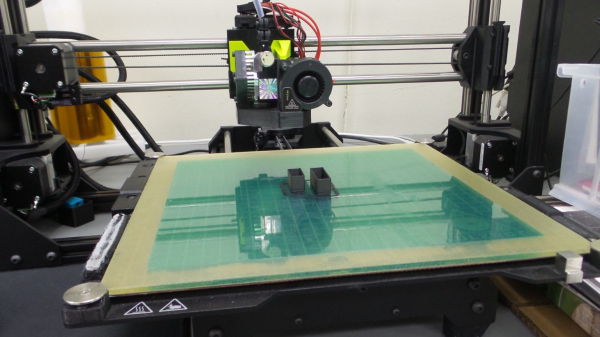

3D Printing & Advanced Manufacturing

Our advanced 3D printing capabilities allow us to produce precision-engineered products, tools, prototypes, and fixtures. PRS utilizes superalloys and high-performance materials for both high-end and cost-effective applications.

Ball Grid Array (BGA) Underfill Services

We provide underfill services for BGA and other low-profile components designed to protect sensitive electronic assemblies against shock and vibration. Our BGA underfill services are highly adaptable and allow us to create the perfect solution for any customer requirement.

Plasma Etchback & Desmear Treatments

Our plasma etchback and plasma desmear services remove drilling residue created during the manufacturing processes of PCBs. Plasma etchback and plasma desmear processes improve circuit reliability in PCBs by promoting good electrical contact, interconnects, and copper through-plating. We also specialize in plasma etchback and desmear treatments for chemically sensitive components.

Form-In-Place Gasket Solutions

Form-in-place gasket materials are dispensed directly onto the PCBA or the PCBA housing to replace standard O-rings and gaskets. Form-in-place gaskets provide greater protection from environmental contaminants and EMI/RFI interference and nearly eliminate the possibility of gasket loss or shift. PRS offers a variety of materials designed to suit your applications’ exact needs.

Removal/Stripping of Conformal Coatings

Conformal coatings may need to be removed from components for several reasons, including repair or refurbishing, failure analysis, functional interference caused by the coating, or incorrect coating application. Using a variety of methods, including solvent-based, physical and plasma coating removal, we can safely and effectively remove conformal coatings from your PCBs.

Request a quote on Plasma Ruggedized Solutions’ production & engineering services today or contact us with any questions you have.

Design, Prototyping, & Engineering Services

We offer a variety of engineering, design, and prototyping services to help optimize your components and assemblies, such as conformal coating for EMI/RFI interference shielding and potting/encapsulation processes. We can assist with everything from materials selection and circuit board layout design to the assembly process and more.

Advanced CNC and Molding Capabilities

- 5-Axis CNC Milling: Our Haas UMC-750SS 5-axis CNC milling machine produces complex, precision-machined parts from aluminum, stainless steel, titanium, and more.

- Custom Molding Services: PRS designs and manufacturers custom molds using 3D printing and EMC machining for improved compatibility and performance.

Polyurethane Conformal Coatings

Our Polyurethane PCB conformal coatings are available in single/two component formulations and provide excellent resistance to humidity and a wide range of chemicals. Our specialized polyurethane PCB and urethane resin (UR) conformal coatings capabilities are ideal for aerospace applications or where exposure to fuel vapors is a concern.

Form-in-Place Gasket Solutions

Plasma’s Form-in-place gasket services are designed to offer better protection for PCBs and other electronic assemblies against contaminants and EMI/RFI interference. Form-in-place gaskets are designed to take the place of conventional o-rings and gaskets and can reduce our customers’ overall manufacturing costs and the potential for product failure.

Testing, Screening & Laboratory Services

PRS provides in-house laboratory analysis and testing for in-process products, failures, and field returns. Our services include:

- ROSE Testing

- Ionic Testing

- Hi-Pot/Continuity Testing

- Cross Sections

- Two-Dimensional X-Ray Diffraction

State-of-the-Art Equipment & Facilities

PRS utilizes cutting-edge technology and high-end equipment to perform conformal coating, potting, encapsulation, and precision machining with superior quality control.

Contact Plasma Ruggedized Solutions for Conformal Coating Services, FIPS Compliance, and More

Plasma Ruggedized Solutions is the industry leader in potting, encapsulation, and conformal coating services for PCBs and electronic assemblies. PRS works across industries, providing solutions to a variety of applications.

Request a quote today or contact us to learn more.

Plasma

Ruggedized

- CMMC Level 2 Compliant

- Missile Defense Agency (MDA) Certified

- NASA 8739.1A Certified

- NADCAP Electronics Certified