Circuit Board Testing Services

Plasma Ruggedized Solutions offers Hi- Potential (Hi-pot) testing and continuity testing services for your completed products and assemblies. Hi-pot/continuity testing are two of many circuit board testing procedures we perform to ensure the quality and functionality of coated products. Hi-pot testing and continuity testing procedures are designed to guarantee industry-standard performance from your devices.Request a Quote

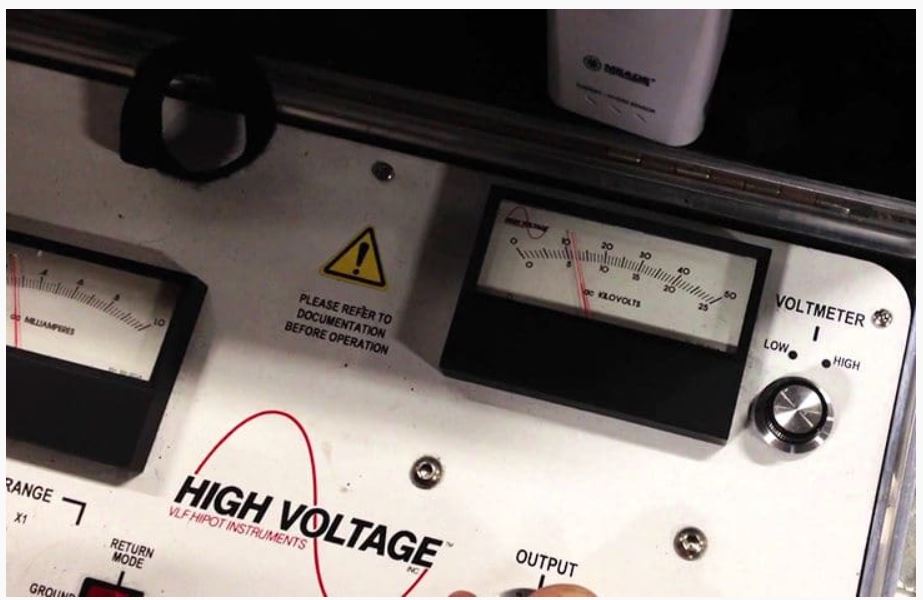

The Hi-Pot Testing Process

Hi-Pot testing assesses the materials used in a component to verify the highest level of electrical voltage these materials can endure before they begin to break down. This safety test determines at what point electrical power will begin to flow across materials that are meant to be insulative, introducing electrical current into places where it’s not meant to go. Plasma Ruggedized Solutions’ hi-pot testing ensures that you product meets voltage isolation requirements for safety and electrical failure measures.

Theses relatively simple in-house circuit board testing processes help determine how much voltage your products’ circuits can accommodate before current leakage and/or breakdown. Voltage testing is conducted to the customer’s requirements, to guarantee compliance at industry-standard levels or higher.

Plasma Ruggedized Solutions continuity testing is used to verify a continuous circuit path for proper performance. This process can be used to test a wide variety of systems to ensure that their electrical pathways are properly connected and those current flows through them correctly. It is a relatively simple procedure, but continuity testing is required for industry-standard certification of electrical products.

Contact Plasma Ruggedized Solutions for Hi-Pot Testing, Continuity Testing, and Other Services

Contact Plasma Ruggedized Solutions for more details on our hi-pot testing/continuity testing services.

Plasma

Ruggedized

- CMMC Level 2 Compliant

- Missile Defense Agency (MDA) Certified

- NASA 8739.1A Certified

- NADCAP Electronics Certified