BLUE SPARK™ Parylene Dimer

BLUE SPARK™ Parylene C is a UV fluorescing parylene dimer material. Providing high-performance, UV parylene dimers are designed to produce a high-purity parylene polymer film with impressive electrical, chemical, and physical properties and allow for inspection with UV light. BLUE SPARK™ UV fluorescing parylene dimer material has been tested and/or certified to meet or exceed the performance requirements of MIL-I-46058C, IPC-CC-830B, UL 94V-0, UL 746, and NASA Low Outgassing (ASTM E595) as a finished CVD parylene film.Contact Us

UV Fluorescing Parylene Dimer Advantages

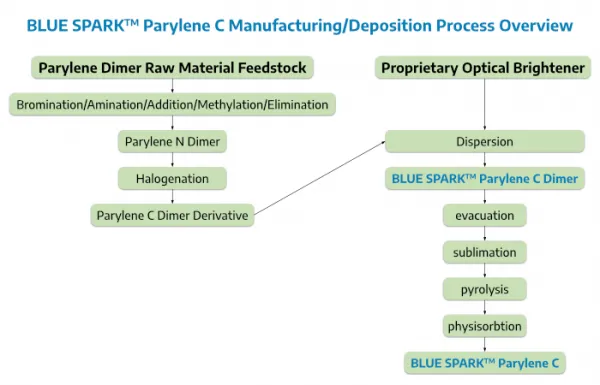

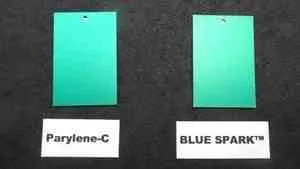

BLUE SPARK™ is a cost-effective and efficient parylene dimer featuring a UV fluorescing tracer. Deposited film using a UV fluorescing agent can be quickly inspected under ultraviolet light. The UV fluorescing agent is an optical brightener that may also collaterally increase the performance of the final film deposit.

BLUE SPARK™ is a cost-effective and efficient parylene dimer featuring a UV fluorescing tracer. Deposited film using a UV fluorescing agent can be quickly inspected under ultraviolet light. The UV fluorescing agent is an optical brightener that may also collaterally increase the performance of the final film deposit.

- UV Fluorescing material provides the ability to inspect finished parylene under ultraviolet light inspection and retain high-performance properties

- RoHS Compliant

- REACH Compliant

- USP Compliant/Conforming

- ISO 10993 Compliant/Conforming

- Tested (Pass), meets the requirements of and is Compliant with MIL-I-46058C

- Tested (Pass), meets the requirements of and is Compliant with IPC-CC-830B

- IPC-CC-830B Certification pending

- Tested (Pass), meets the requirements of and is Compliant with Flammability Standards for Self-Extinguishing MIL-I-46058C (ASTM D635), and UL 94V-0

- Tested (Pass), meets the requirements of and is Compliant with NASA Low Outgassing criteria (ASTM E595)

- Cryogenic Compatible

- Vacuum Stable

UV fluorescing parylene dimer, BLUE SPARK™, can also be used with coating and underfill services from Plasma Ruggedized Solutions. Ball Grid Array (BGA) underfill services provide additional protection to sensitive circuit boards using Kronos-10™, an in-house specially formulated underfill material. Plasma Ruggedized Solutions also manufactures Kryptos-17™, a two-part electric potting material that enhances operational protection in harsh environments. Conformal coating services, including individualized coating services for aerospace, also offer increased protection for circuit boards using parylene dimers.Request a Quote

UV Parylene Dimer Physical Properties

UV fluorescing BLUE SPARK™ parylene dimer provides specialized tin whisker mitigation performance in a thin film solution. Offering exceptional resistance to water, salt spray, inorganic acids, organic solvents, corrosive gases, and other environmental threats, UV parylene dimers protect sensitive electronic applications in harsh conditions.

BLUE SPARK™ Increased Adhesion Strength

BLUE SPARK™ offers increased adhesive strength over conventional untreated Parylene dimers without the addition of adhesion promoters/additives. This attribute can be further enhanced during the proprietary dispersion process of manufacturing through vacuum plasma and special adhesion promoter processes.

Key Technical Specifications

For complete performance data, download the BLUE SPARK™ Technical Data Sheet (PDF) .

| Property | Value |

|---|---|

| Tensile Strength | 9,800 – 10,000 psi |

| Service Temperature (Continuous) | 105°C / 221°F |

| Service Temperature (Intermittent) | 130°C / 266°F |

| Dielectric Strength | 6,400 – 6,700 V/mil |

| Water Absorption (24 hr) | 0.06% |

| Water Vapor Transmission | 0.10 (g·mm)/(m²·day) |

| NASA Outgassing – CVCM | 0.00% |

| Purity | ≥ 99.65% |

| Shelf Life | 5 years |

Industries Using BLUE SPARK™ UV Parylene Dimer

With a host of advantages, UV parylene dimers are helpful in many applications across various industries. Industrial applications that benefit from using BLUE SPARK™ include:

- Military applications & electronics

- Aerospace hardware & electronics

- Medical applications & electronics

- Network communications applications & electronics

- Consumer hardware & electronics

Applications utilizing UV fluorescing parylene dimers to produce conductive films save time and cost in equipment and personnel. The UV tracer simplifies film inspection and may increase the performance of the film deposit. Request a Quote

Increased BLUE SPARK™ Adhesion Strength

An essential attribute of the PRS product is adhesion capabilities. BLUE SPARK™ UV parylene dimer enhances adhesive strength over traditional untreated parylene dimer options without adhesion promotors and additives. Adhesiveness can be increased during the proprietary dispersion process of PRS manufacturing through additional processes involving vacuum plasma and a special adhesion promotor.

Contact Plasma Rugged Solutions for UV Fluorescing Parylene Dimers

Plasma Ruggedized Solutions is a customer-centric FIPS-compliant company. We can manufacture parylene dimer solutions and offer additional services that protect sensitive circuit board applications in challenging environments. Contact us for more information regarding our BLUE SPARK™ UV fluorescing parylene dimers, or request a quote today. Contact Us

Plasma

Ruggedized

- CMMC Level 2 Compliant

- Missile Defense Agency (MDA) Certified

- NASA 8739.1A Certified

- NADCAP Electronics Certified