Parylene Coating Services

Parylene Technology - The Coating Process

Parylene Coating System

What is Parylene Coating?

Parylene conformal coatings offer cutting-edge solutions to safeguard and enhance the performance of critical components, devices, and surfaces. Unlike traditional coatings, parylene is created at room temperature to eliminate the need for a liquid phase during application, enabling the coating to penetrate even the narrowest spaces for comprehensive, uniform coverage. Our parylene coating solutions are chemically inert, biocompatible, and FDA-approved for use in medical implants, as well as compliant with NASA’s low-outgassing requirements for vacuum environments.

Contact Plasma Ruggedized Solutions today or keep reading to find out how our Parylene conformal coating services can benefit your company’s products.

What is Parylene Coating?

Parylene coating is a vapor-applied conformal coating that protects critical components with uniform, pinhole-free coverage—even in ultra-tight spaces. Plasma Ruggedized Solutions offers Parylene C, D, and N, which are chemically inert, biocompatible, and FDA-approved for implants. Ideal for medical, aerospace, and optical applications, these coatings meet NASA’s low outgassing standards and ensure long-term reliability in harsh environments.

Options for Parylene Conformal Coating Materials

Parylene C

The sister product of Blue Spark™, parylene dimer, parylene C offers the same high-performance, high-purity characteristics without the added UV tracer material. This coating material creates a thin-film solution with excellent resistance against corrosive gases, inorganic acids, water, salt spray, bases, and organic solvents. It is designed to withstand harsh environments and can be paired with silicone or polyurethane for abrasion-resistant solutions.

Parylene N

Parylene N is made with carbons and hydrogens, delivering a higher dielectric strength than parylene C. Due to its higher molecular activity, this coating material offers greater crevice penetration and can include a UV tracer for simplified visual inspection using a standard UV light source.

Parylene D

Parylene D features carbon and hydrogen and two chlorine groups to its benzene ring, which are also para-substituted. With properties similar to parylene C, this coating material can additionally withstand high temperatures, but has a lower dielectric strength with the same level of surface resistivity.

Parylene HT

Substituting the alpha hydrogen atom of parylene N with a fluorine atom creates parylene HT, also known as parylene F. It is a valuable coating solution for high-temperature applications and scenarios that require long-term UV stability, offering temperature resistance up to 450°C. This parylene formulation features the lowest coefficient of friction and dielectric constant with the highest penetrating ability compared to other parylene formulas.

High-Performance Parylene Coating Applications

Used in applications spanning various industries, parylene coatings can protect assemblies such as implantable medical devices to equipment designed for deep-sea operations. Parylene is the preferred conformal coating material for medical applications, providing biocompatibility and a long-standing history with little risk of complications. In order to support your conformal coating needs, we provide parylene coating services for the following applications:

- Surgical devices

- Human implantable devices

- Printed circuit boards

- Various electronic equipment

- Marine applications

- And more

Advantages of Parylene Coating Services for Assemblies

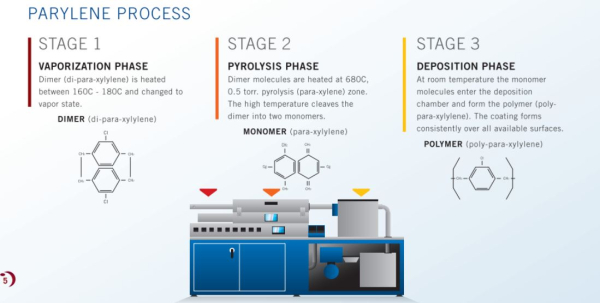

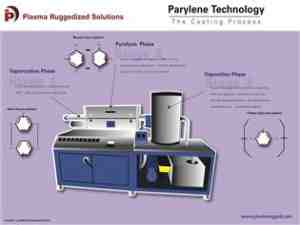

Parylene coatings are applied in a vacuum deposition process, heating the solid parylene to a vaporous state and recondensing it on the target assemblies. This process offers several advantages over wet-process and dip-process, making it resistant to hostile environments with high chemical resistance, insulative properties, uniformity, and improved coating durability. The benefits of parylene coating services include:

- Superior and consistent product quality

- Uniform in thickness and pinhole-free

- Dielectric strength exceeding 6000 volts/mil

- Provides water resistance

- Thorough coating without increasing size or loss of material thickness

- Excellent mechanical properties and thermal stability

- Resistant to acids, alkalis, gases, and fungi

- Highly adaptable

Parylene Coatings Deliver Proven Effectiveness Across Industries

Easily penetrating and adhering to a range of substrates, parylene is compatible with glass, metal, plastic, elastomer, and more for use in various industries. Parylene delivers precision application and enhanced endurance features, like biocompatibility for implants, and water resistance to protect avionics and electronics, providing a preferred solution for medical and military operations. Industries that frequently utilize parylene coating services include the following:

- Medical

- Military

- Electronics

- Aerospace

- Automotive

- And more

Physical and Mechanical Properties of Parylene Conformal Coatings

There are three types of Parylene conformal coating that are frequently used: Parylene C, Parylene D and Parylene N. Parylene C is more widely utilized across different industries because it is cost-effective and highly versatile. Parylene N is next, with Parylene D being used less frequently than the others.

| TYPICAL PHYSICAL AND MECHANICAL PROPERTIES | |||

| Parylene (N) | Parylene (C) | Parylene (D) | |

| Tensile Strength, psi | 6,500 | 10,000 | 11,000 |

| Tensile Strength, MPa | 45 | 69 | 76 |

| Yield Strength, psi | 6,300 | 8,000 | 9,000 |

| Yield Strength, MPa | 2,400 | 3,200 | 2,800 |

| Elongation at Break, % | 40 | 200 | 10 |

| Density, g/cm3 | 1.110 | 1.289 | 1.418 |

| Coefficient of Friction: | |||

| Static | 0.25 | 0.29 | 0.33 |

| Dynamic | 0.25 | 0.29 | 0.31 |

| Water Absorption, % (24 hr) | 0.01 (0.019") | 0.06 (0.029") | <0.1 |

| Index of Refraction, nD23 | 1.661 | 1.639 | 1.669 |

Why Work With Plasma?

While our state-of-the-art material application concepts are constantly evolving, we have always operated on four major structural pillars:

1. High-quality NADCAP, AS9100 and NASA-certified engineering services.

2. A constant drive for developing process and safety control.

3. A quality first/customer-centric mentality centered on open and honest communication.

4. Continuous improvement performance (CIP) culture for the empowerment of both our customers and employees.

Contact Plasma Ruggedized Solutions for Parylene Coating Services for Your Products

As an industry leader in conformal coating, Plasma Ruggedized Solutions offers over 20 years of experience in parylene coating services. Working across industries, we provide innovative solutions for plasma technologies, full-service manufacturing and fabrication, and more, including problem-solving components and subassemblies to exact specifications. Our team has decades of expertise, understanding your challenges and working with you to address any concerns.

Contact us to learn more about our proprietary materials or to discuss your project requirements, or request a quote to get started.